We can offer pinned tooling for existing hot perforation as well as new custom pinned tooling and complete machines for hot needle perforating.

Hot-needle perforation allows a poly-based material to be permeated with a hole that will not close up and this is the perforation method of choice in applications where aesthetics are key. The hole which is left by a hot perforation needle is re-enforced by a neat, molten ring of material that surrounds the hole. Hot needle perforation is used in a wide variety of applications. Perforations can be made in register or in a continuous pattern.

– Filling of powder materials

– Bakery good packaging film

– Fresh-cut flower wrapping film

– Hygiene and Medical Industries

– Other food packaging

– Other operations which require moisture, vapour or air flow control

These hot needle machines can be made up to 2000mm wide as standard. Custom machines can be manufactured for large diameter rollers in the case of high speed applications or applications that demand greater width to overcome roller deflection. Perforators can be made to bolt into existing lines or we can manufacture them with our range of unwind and rewinds for stand-alone operation.

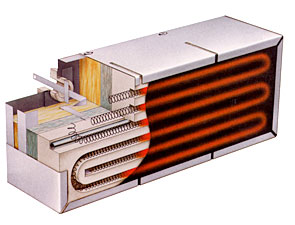

HOT PERFORATION UNIT:

PINNED ROLLER:

Pinned Roller heated by I.R System

COLD PERFORATION SYSTEMS:

This technology is used in many applications and allows the substrate to be perforated with a raised surface on either side of the material. Perforations can be made in register or in a continuous pattern. Cold perforations can vary in size and can be made in many different patterns. The most common are square and diamond. Our machines are designed with quick change tooling, allowing the operator to safely change the pinned sleeves without damaging him/herself or the pinned sleeves.

The cold perforation process often uses a backup pressure roller. We can supply polished steel rollers, hard urethane rollers, brush rollers, rubber rollers and grooved rollers to suit your perforating process.

These cold needle perforation units can be made up to 3000mm wide as standard. Custom machines can be manufactured for large diameter rollers in the case of high-speed applications or applications that demand greater width to overcome roller deflection. Our machines are precise, simple to use and utilize wearing parts that are available off the shelf and can be obtained internationally.